UPDATE!

Well, finally went to the track... lasted 4 laps

Here's the long story, had all summer to do whatever prep I wanted but kept putting it off

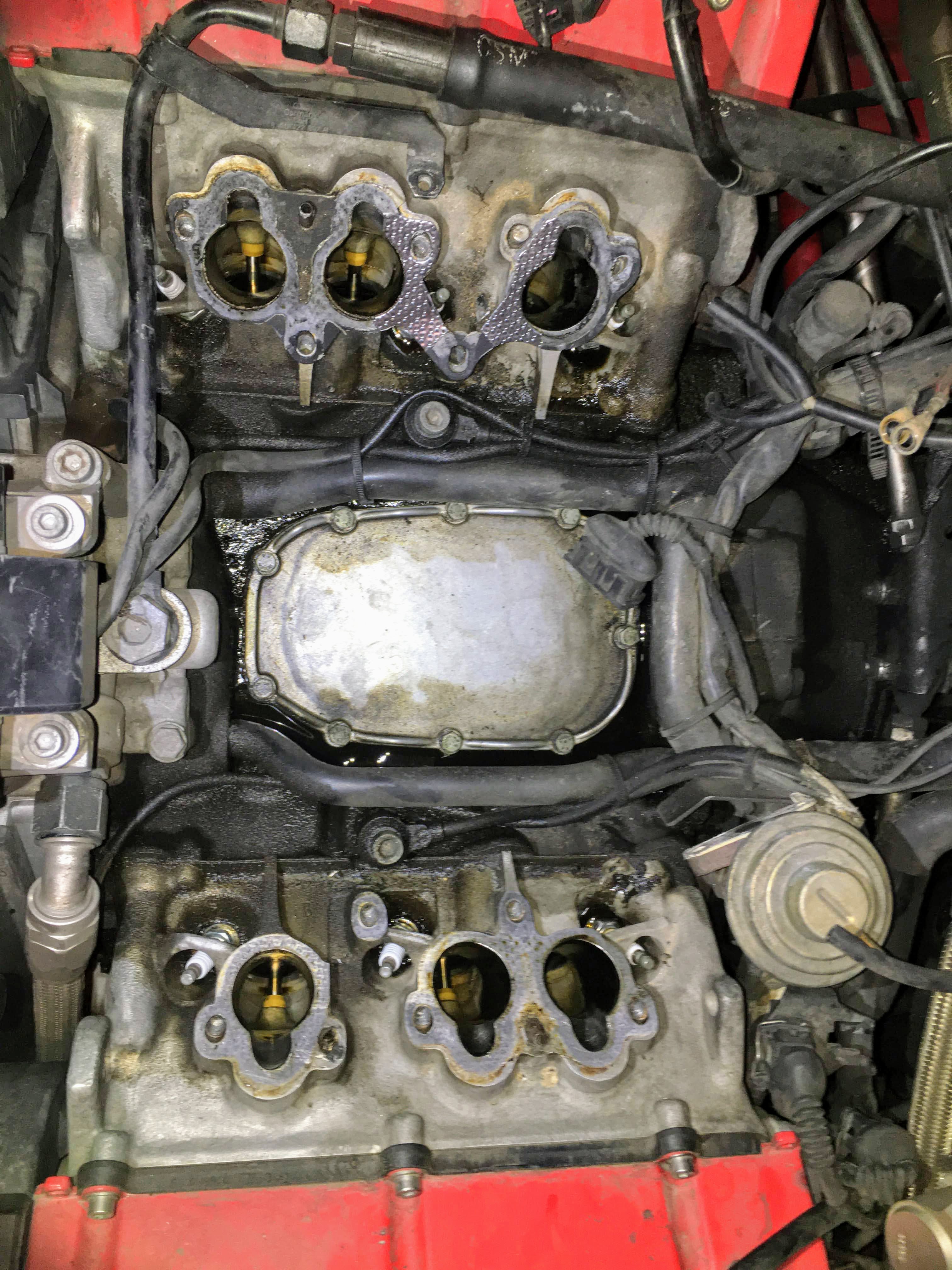

When I finally had to get ready I decided to pull the IM to inspect a persistent oil drip, ended up being a larger leak so I re-did the valley pan as it had been a few years.

- A bit of oil

- IMG_3029.JPG (1.09 MiB) Viewed 44576 times

Getting new gaskets took a bit so it was somewhat a push to get ready for the track and I didn't have much time to generally go over things (which I regret now). So, loaded up and leave for High Plains Raceway (HPR). After about a block, I realize something is off and pull over to find a very hot cat.

- Dead hole

- IMG_3041.jpg (596.58 KiB) Viewed 44576 times

Re-review wires on the DS bank, found I swapped 2 plug wires (bad googleing) so only a slight delay. I hoped that was the last issue for the day but it ended up being a sign of things to come

The hour drive to HPR was uneventful, caught up to a group from Bluewater Performance towing the PIHC S3 so was excited to get the chance for a closer look at that car. Unload, drivers meeting, line up for lead follow since I'm a newb.

Lead follow starts out fun, lead car is a C6 vette, the 90 feels good but focusing on learning the line and trying to keep up with the group. Since almost everything has more power than the 90 it was challenging to maintain momentum through corners while the rest of the group really could rely on powering out of every corner and down the straights. Still, I made due and felt better once I got to the front of the line where I was only subject to the instructor's braking. About half-way through the next lap, I was back at the end of the line, something felt odd and under breaking for turn 8 (a nearly 180º left) a wheel locks hard. Luckily I was in the back and kept control to pull to the apron. I figured, hoped, it was a flat but the flatbed driver didn't see one. Once back in the paddock, it was quickly obvious that the caliper was not where it should be

I scrambled to pull everything apart and see WTF happened and I found a broken aluminum adapter bracket. I'm fairly sure I would never have noticed the corroded bracket during a routine review so I felt less bad about running out of time.Since it was early and my friend's wife was just hanging out, I started calling parts stores thinking I could pull the adapters and downgrade to stock B5 S4 rotors. We found a set, and pads, at the closest town so we headed to grab them. By the time we got back it was lunch but I started trying to bolt things together after a quick bite. To my dismay, the rotor was not lining up with the caliper. At the time, I figured the issue was a variant in S4 rotor and since there were no others in the area we decided to we'd tow the 90 home and I'd pilot the C5 Z06 track car back to his house. At some point, I rode along for half a session in the Z06. Seems like a nice base for a track toy, he's basically stripped it to install the harness bar and seats and added some heat management.

Since I spent most of the day running for parts and messing with things, I took the chance to get a ride along in the BWP PPIHC S3. Robb Holland was at the track doing laps but I ended up with another, still skilled, driver who's name I missed. Still,

what a fiddlesticking car! We did about 3 laps and it was insanely fast, point and shoot, awesomeness

Almost worth the trip. Can't wait to see what they build for next year!

At this point, we loaded up and headed home.

- Loaded up

- IMG_3039.jpg (902 KiB) Viewed 44576 times

Driving the Z06 home was entertaining, not the best street setup but manageable. The shifter is tight, he's trying to improve that in the off season. An hour on the highway is dull but I'll have to get some seat time in at the track next season.

The cherry on top of the bad day was that I somehow lost the Harry's Lap Timer recording of my laps

Now that I've had a chance to dig deeper, I've remember/discovered that Mance made his own bracket. Unfortunately, with B4 hubs I cannot bolt on any B5 rear BBK because the flange spacing is ~0.25" different. Of course, this is after I bought the Apikol B5 rear BBK thinking it would bolt up

So the question is, should I:

1. Have somebody make a, steel, bracket to adapt for B6/7 rear rotors (I don't really want to rebuild the ECS rotors)

2. Swap to B5 hubs and risk clearance issues with the fender (requiring different wheels or narrower tires) so I can use the Apikol kit

3. Find some 5x112 rotors (or re-drill) which work with the B4 hubs, even if they are stock size

I suppose a 4th option would be to try and shim things into alignment but that feels less like doing it right.

My goal is to get back to an early spring track day, I was hoping to honestly evaluate the 90 on track to better understand what I want to do next. I think I'm ready for a new experience on the street but that may be in addition to the 90.