Update time, the good, bad, and ugly edition.

Rolling back to early September, I had a complete motor to rebuild including finding a good set of OEM 3B/AAN pistons, receiving a cylinder head that Hank and Jim conspired to set me up with, and figuring out an installation for the EFR7163 I had just received. I got to work, hoping to avoid stress and scramble of BBQ6 by having the car together and driving something like a week before the event. Ha ha ha, yeah right.

The solved the header issue by ordering one from Iroz. I seriously considered building my own, but when I added up material costs and factored in the learning curve of making a collector, primaries, welding everything, and the logistics of getting everything together to come up with packaging...spending $1200 to buy a product proven to last, make power, and be easy to work with became the obvious choice. I ran up to Vegas on October 1 to pick up the completed header and cylinder head to get started.

The piston issue was a bit of a struggle. I had previously had my bottom end balanced together, and wanted to make sure that was maintained when replacing my burnt #5 piston with the new build. I procured a little digital scale that measures to .1g, and got to measuring my old set of pistons and a complete new set I got off of Facebook. I found each sets of pistons to be well-matched within themselves, with a spread of about 0.8g between the lightest and heaviest piston in each set. However, the two sets weighed an average of about 6g different from each other. Visually and dimensionally I could not tell any difference between them aside from a small 'nub' of material on the wrist pin boss, and the heavier set having a '+' stamped into the crown while the lighter set had a '-'. I tried grinding away at the heavy set trying to get one within 1g of the average of the lighter one, but it turns out aluminum is not very dense and after removing more material than I was comfortable with from the wrist pin bosses and lower skirt, I had only removed around 2.5g from the lightest of the 'heavy' set. No bueno.

I put the feelers out again, and found a local guy with an AAN shortblock that had '-' marked pistons. I paid $100 for it and thought I stole it for that price as it came with a good damper machined for a 60-2 trigger wheel, an oil pan, and the block itself was totally rust free. Unfortunately I found it did have a scored #4 bore, so it wasn't useable this go around. However, I found a piston that was within 1g of my four old pistons, so I was in business. I started assembling the motor at 10pm October 9, 11 days before we were to depart for BBQ. It turns out these motors are pretty simple to put together, with all the parts fully prepped I think I had about 6-7 hours of labor into completely assembling a longblock. I was surprised, having been used to Porsche engines taking a solid 20-30hr of assembly in the day job.

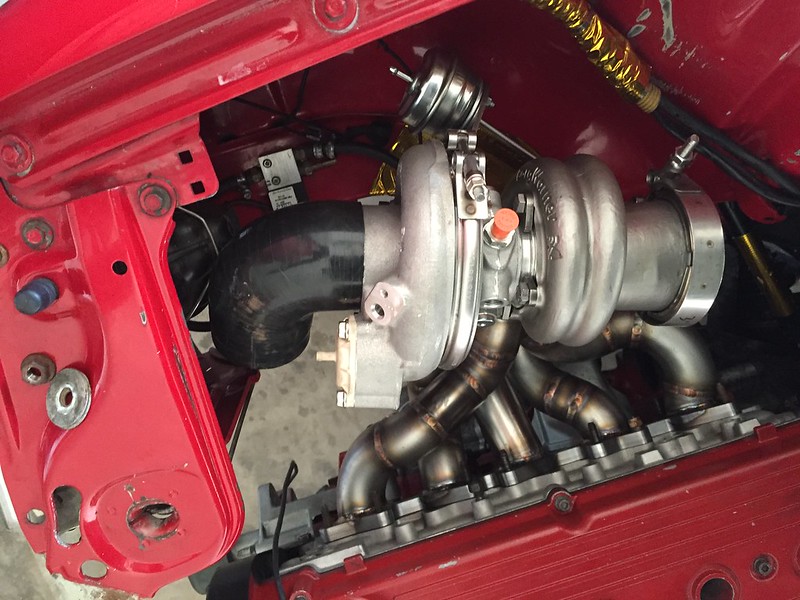

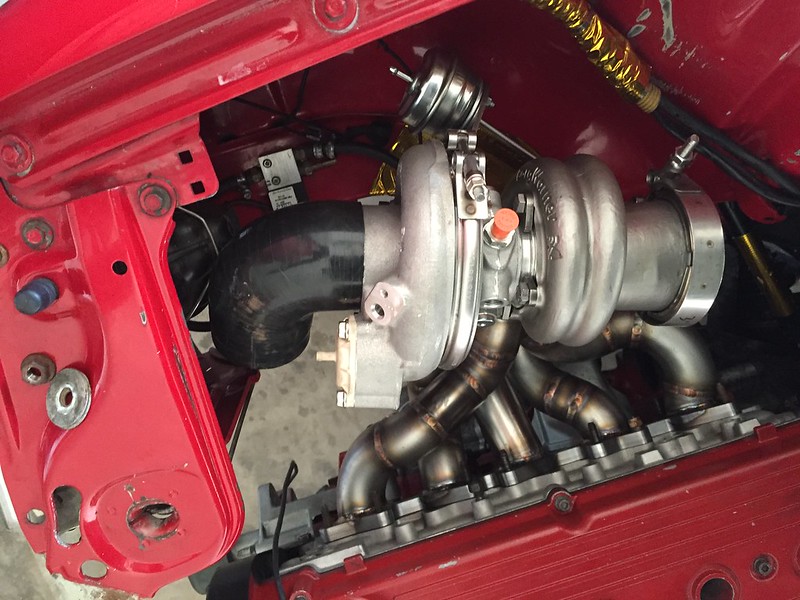

The engine went in the car October 12, and focus immediately turned towards getting the new turbo/exhaust installed and packaged. The Iroz header is well designed to make it easy to package and intake and exhaust in a small car, but the reality is that the EFR is just a really long turbo. Long hotside for the IWG, long CHRA, and long compressor housing because of the integrated BPV, all adds up to a turbo that is almost 11" long. In addition, the 7163 does not use an anti-surge compressor housing, instead using a 2.50" OD inlet. Nobody makes tight radius 'cobra head' hoses with a 2.5" ID on the 'turbo' side, so you're stuck using a full size elbow which is VERY tight against the back of an RS2 headlight. Initially there was a large interference, but I moved the engine and trans as far back as they would go on the motor mounts. It should have been there anyways for reasons, but at some point during all the engine/trans swaps it ended up being quite far forward. I got almost an 3/4" of frontal clearance by doing this and it made the turbo inlet a lot more workable. This was completed Saturday, October 15, less than a week before BBQ7.

At that point, I felt comfortable moving ahead with the rest of the installation, which included making turbo oil and coolant lines, the exhaust, and intake. For the turbo lines, I went with brand new black anodized fittings and black nylon covered hose and topped it with black fire sleeve. It looks great, but the black fire sleeve does tend to attract a lot of dust. I used VIbrant for some of the fittings, which I would not recommend as they were a pain in the ass to put together as they don't have the lefthand threads in the collet like other brands do. I made them work, though.

For the exhaust and other fabrication, I went with Ryan of Jakey Products in Phoenix, AZ. Jakey develops and builds exhausts and headers for us at Evolution Motorsports. I really like how he does things and he has an awesome shop. He practically begged me to have him build a new exhaust for the car at a great price. It was to be a full mandrel bent, TIG-welded 304-stainless turboback system using a muffler he builds in house. Can't say no to that. Car went to him Sunday, October 16, five days before leaving for BBQ7.

He spent about two full days building everything, and the system turned out beautiful. The downpipe has about four bends in it, going between the engine, trans, frame rail, and axle with more than an inch of clearance everywhere. The center and rear sections are fairly straight forward, with solid hangers and lots of clearance everywhere.

He also built a new turbo discharge pipe, and turbo inlet pipe, both out of aluminum. The discharge pipe fits extremely well, having about three bends in it to conform to the space available. The turbo inlet is a work of art, transitioning from 2.5" to 4.5" through a pair of compound bends to mate up to one of our large, dry element V-Flow conical filters and its matching venturi. It fits down right next to the intercooler, in a perfect spot exposed to lots of cool air but protected from dirt/water by the bumper. He made it up by eyeballing it in about 30min, and it is a piece I would be truly challenged to make myself. Anyone in the southwest looking for quality fabrication, Jakey Products' number is 602-687-8270 and he will do you right.

Ryan finished the exhaust on Tuesday, October 18 but needed the car the next day to finish some minor details. I stayed late on Tuesday night to get the car fired. I filled oil and coolant, cranked over to get good oil pressure, and then installed plugs and connected coils and injectors to start the car. It fired up, but had a wicked lifter tick and ran on four cylinders. Total dead miss that I narrowed to cyl 5 with a wet spark plug. I did a ghetto compression test by hitting the starter with the plugs in and injectors disconnected, and there was an obvious skip from a cylinder with low/no compression. Dejected, I went home at 11:30pm, believing I may have bent a pair of intake valves, as I turned the engine over by hand with the cams off a tooth during assembly and ran into interference.

Wednesday rolled around and I got to work. My dad flew in at noon to join me for the weekend, and I informed him that we were preparing to pull the cylinder head to replace some valves. I ordered a head gasket kit and a pair of 323mm A8 brake rotors to allow installation of my 996 C2 brakes...because why not? We rented a compression tester, loaded the car up from Ryan's shop, and prepared to do the maybe-possible-definitely-difficult 36 hours before we were destined to leave for Vegas. We got home at 7:30pm, had dinner, and got to work with a compression test before everything came apart. The results were 90psi, 90psi, 90psi, 90psi, and 90psi...wtf? The low results were not unexpected given a brand new motor and questionable rental tester, but they were even! I threw the plugs back in and the engine purred to life.

. 20 minutes later we were rolling around, breaking in the new engine. An hour later that was done and all looked well. No leaks, no drips, no issues...just 7psi of boost with the wastegate backed almost all the way off.

Thursday, the day before departure, I went to work while my dad stayed home and did some odd jobs. The EGT probe got connected, blower motor replaced, and he started work on doing the BBK. I got off work, and we changed the oil and worked on the BBK for a while longer. We ran into an issue not having long enough M12x1.25 hardened bolts to secure the new caliper brackets to the uprights, so we had to backtrack a bit and put the stock G60s back on. I ordered bolts off of McMaster Carr after the event and everything else is ready to go when I get around to it. Calipers are 996 C2 bought off eBay for $400/pr with almost new pads, rotors are Brembo 25644 purchased from Autohaus AZ, which are 323x30mm rotors with internal venting. They were about $100/ea. The calipers will need paint eventually, but most of them do.

Anyways, with that we gave the car a good wash and left for Vegas around noon Phoenix time on Friday.

It was pretty hot, as the car doesn't have A/C or even tinted windows and it was in the low 90s. We kept the ventilation moving and it wasn't awful, but not very comfortable. I did barely any tuning, mostly increasing WGDC to get a little more boost (about 15psi is all I got electronically without messing with the wastegate), but it was a little off. The car ran a little warm as a result, but never overheated. We hauled ass from Kingman to Vegas in a good pack of cars, doing 95-100mph the whole way.

Thanks Alex K of Vex Art for another set of awesome event photos!!!

We arrived at Audi Henderson a little ahead of everyone else with a screaming power steering pump. I guess running along at 4500rpm must have bled the power steering or something. A $25 bottle of power steering fluid later, the reservoir was filled but it was making some nasty noises like the pump was dead. I noticed a little puddle of power steering fluid under the front of the car further showing issues. I thought about cutting the belt but my dad talked me out of it, which was good.

I might be preaching to the choir a bit, but Battleborn Quattro is truly an amazing event. It is so cool to be able to get together with a bunch of great people from around the country to hang out and share our passions, then go enjoy them as a group for a day is a highlight of my year. The event is quite casual and well-paced, and the last two years I've done things I never would have known about before and will cherish the experiences for life. It is well worth the money, blood, sweat, and tears for anybody reading this to make their way out to the event, even if it's to ride with someone else--it will be a pretty cool ride in something you'll appreciate.

Anyways, we got a good night's rest at the hotel, and got up early the next morning to run out to Cars'n'coffee at Speed Vegas southwest of town. Speed Vegas is an exotic car experience, with a half dozen fancy cars and a road course to drive them on. Hosting CnC there is genius as you get a bunch of gearheads standing next to a track watching cool cars run around. Excellent sales tactic. On our way to and from the event we did some light tuning, getting full throttle fueling dialed in and boost raised up to peak around 20psi, though tapering heavily to 14-15 on a wastegate actuator that is too soft for high boost use. EFR users, buy the Turbosmart part. I was beginning to be very pleased with the EFR, in 4th and 5th gears it makes 1bar by 3500rpm (without spool valve at this time), and the transient response is VERY good. Once the power it's capable of comes in, I should be very happy in how it achieves my goals--power of my old 30R with much better response.

At some point during the morning, the power steering pump went silent and stopped leaking. Seal conditioner in the $25 power steering fluid? Not sure, but not complaining.

This year's BBQ7 drive was up and down Mt Charleston, which is north of Las Vegas about an hour. We had a great drive out to the mountain, punctuated by a small threshold braking issue by a participant. The drive up the mountain was fairly leisurely, not quite the same pace as what we did last year in the Valley of Fire with Ben and Wiley, but a great drive all the same. Definitely gave everyone's standalone tune a workout coping with altitude (~8000ft). I dealt with this last year driving back through Flagstaff at 7000', so everything worked great and the car had no issues all day. Saturday evening was steins of beer at Hofbrau Haus with the whole party. Jim, Brendan, Wiley, Peter, Marc, and Hank are excellent drinking (or not in Hank's case) buddies.

The next day my dad and I ran through the Valley of Fire, and then I swapped seats so he could drive home while I tuned. I made some good progress with tuning and got driveability way up and engine temps down. With the wastegate cranked down and 95% WGDC, I got a peak of just over 20psi which made the midrange VERY punchy at freeway speeds. We made it home no problem and grabbed the best Mexican cuisine in Phoenix.

I spent the next few days getting caught up with work, but drove the car on Thursday intending to turn up the wick and enjoy it a bit. After hours I took it out with my coworker Matt and ripped around our industrial complex for about 30min. We were having a blast and the car was running great when all the sudden it made a huge backfire and then a horrible banging noise. Motor died, no compression while cranking. Fck. A quick autopsy found that the cam gear bolt had broken in two, causing the cam gear to break and presumably hosing the top end that had six days and ~800 miles of use on it.

I posted this on Facebook and conjecture flew. That bolt is one-time-use! It must have been overtorqued! Use aftermarket bolts! Ten years ago I would have believed all of that, but since then I'm pretty diligent when it comes to carefully assembling this stuff per factory specs. This bolt had been in and out a number of times, but had never been overtorqued and as far as I've known is not a common failure point/wear item. I was pretty puzzled, but dropped it for a couple weeks while I went on my honeymoon and worked on my business.

This week I finally got a chance to get the car home and tear it down, and got some hard answers. The good news is that the failure makes total sense, but the bad news is I caused it by screwing up the assembly. I mentioned before i had to retime the cams during assembly as they were put together a tooth off. Well, it appears that when I did that, admittedly pretty tired and exhausted by my full time job and the task ahead of me, I neglected to torque down the exhaust cam caps. One of the nuts came off and got wedged between a cam lobe and the head casting, which presumably caused the cams to bind up, gear to fail, and bolt to break. Fortunately, this appears to have happened pretty suddenly, as only two intake valves bent despite the engine having been at 5000rpm when the failure happened. I have a head full of good intake valves in the garage, so I'm home free, right?

Unfortunately, I found some much worse news while cleaning up the bottom end. The #2 cylinder bore has a huge scratch in it that can only be explained by a problem with the wrist pin circlip--either the clip or the wrist pin are wearing into the cylinder wall. The damage is pretty deep, estimate 0.5mm. Game over for this fresh bottom end, and I either need a new 81mm block to put a set of OEM pistons in, or I need to nut up to bore one of the two blocks I have, buy some pistons, and rebalance everything. Neither is cheap, and as the holidays are coming up and I'm still recouping from the major build I just got done doing, this project goes on the back burner for a few months. Woe is me.

So, if anyone has a line on a good 81mm block in the southwest, let me know. Until then, 11 months until BBQ8!

Sam