Page 13 of 43

Re: Eric's '90 80QT-to-be: fark air conditioning

Posted: Sun Aug 19, 2012 8:28 am

by elaw

Well here's an unsolicited opinion for you all: IMHO anyone who has managed to keep A/C in one of these cars with a turbo motor and 016 transmission deserves a Nobel prize!

It's well known that the intake manifold on an AAN has clearance issues with the radiator in these cars, and adding an A/C condenser to the radiator only makes things worse. What's less well-known is that if you want to keep the AANs serpentine belt setup, the bracket for the alternator and A/C compressor also creates issues. I was prepared to deal with those.

Next issue is the high-pressure line going from the condenser to the evaporator. It runs left-to-right across the firewall just under the steering rack. But guess what, the 016 shift linkage occupies the same space. So that line needs to be bent or something... I hadn't quite figured it out yet.

Today's task was to install the oil cooler, but I realized that if I wasn't careful, I could put the cooler in a place where it would interfere with the A/C accumulator or the line going from the accumulator to the evaporator. So in a rare moment of smartness, I figured I better install that accumulator and line so I don't intrude on the space they need.

The line is in 2 pieces with a joint in the middle. It appears the joint needs to be separated to install the line, plus the person I bought it from had loosened the joint a bit already but it was stuck so I needed to get it freed up. My strategy was to get it completely apart, clean up the threads, and reassemble it with anti-seize so it would come apart easily in the future. Well I got it apart all right, but it's never going back together:

The photo pretty much tells the story: there ain't no threads left to clean up!

I've dealt with joints like this on many other cars where the "nut" part of the joint was steel and they had horrible issues with corrosion (and resulting thread damage) due to the metals being dissimilar. But apparently Audi has some very talented engineers that can design a joint that corrodes even though it uses the same metal for both parts! :slap: :(

Re: Eric's '90 80QT-to-be: raising the bar

Posted: Sun Aug 19, 2012 8:31 am

by elaw

mrmotorhead13 wrote:I'm inclined to think the snubber wouldn't get much snubbin from that crossbar, Eric. Looking at it I suspect it would bend with any real load on it. Any way to run a brace or two from the vicinity of the snubber bracket bolts up to the OEM crossbar, or does that negate the ability to fit the intercooler?

Well I'd thought about that but decided I'd give it a try and it's actually pretty rigid. The angle is 1/8" thickness so it's not super-beefy but I think it's good enough.

I have thought about making brackets to go between it and the stock crossmember (or its replacement) but that depends on what intercooler I end up using. I still may go with the ebay unit, if I can get it to fit behind the bumper. One of my motivations that I didn't mention earlier for using the Saab intercooler is that it would not require cutting up the bumper cover which IMHO looks awful.

Re: Eric's '90 80QT-to-be: fark air conditioning

Posted: Sun Aug 19, 2012 9:54 am

by JonathanL

Hey Eric I have all my 91 a/c stuff I didn't cut any of it you can can have it if if you wanna grab it. Pay shipping it yours or come get it

Re: Eric's '90 80QT-to-be: fark air conditioning

Posted: Sun Aug 19, 2012 5:10 pm

by elaw

On a related unrelated note... can anyone with a 20V car confirm that the A/C accumulator is in the same location as in my car?

That would be here:

...behind & below the passenger's headlight inside the frame rail.

I saw something that makes me think that the 20V ones are mounted on the outside of the frame rail (basically inside the fender)?

Re: Eric's '90 80QT-to-be: fark air conditioning

Posted: Sun Aug 19, 2012 5:29 pm

by yodasfro

Nope it's in the same spot on the 20v. On the S2 it's on the outside.

Re: Eric's '90 80QT-to-be: fark air conditioning

Posted: Sun Aug 19, 2012 7:17 pm

by mrmotorhead13

Looked at my 90Q 20V just now Eric... that's right where mine is located.

Re: Eric's '90 80QT-to-be: progress!

Posted: Mon Sep 03, 2012 3:50 pm

by elaw

A while back I alluded to a solution I've come up with for dealing with the idler pulley for the serpentine belt. It took a couple of iterations to get it right, but I can finally present you this:

On the left is an aluminum piece I had made up that goes in the AAN alternator/AC bracket in place of the factory idler and its bearings. Onto the front of the new piece piece attaches a Saab serpentine tensioner pulley, shown in the photo with the funky bolt and washer that are used to hold it in place.

Installing it requires cutting a little off the "nose" of the AAN bracket:

The aluminum piece slides into the AAN bracket and is held in place with bearing retaining compound and a setscrew. The end result looks like this:

The other "fun" part about this setup is that due to the pulley being smaller, a shorter belt is required. Previously on this engine I was using a 51.2" belt. Now it uses a 50" one.

Re: Eric's '90 80QT-to-be: progress!

Posted: Mon Sep 03, 2012 4:03 pm

by DE80q

Very nice, so how many prototypes did it take until you got one that worked?

Re: Eric's '90 80QT-to-be: progress!

Posted: Mon Sep 03, 2012 4:05 pm

by elaw

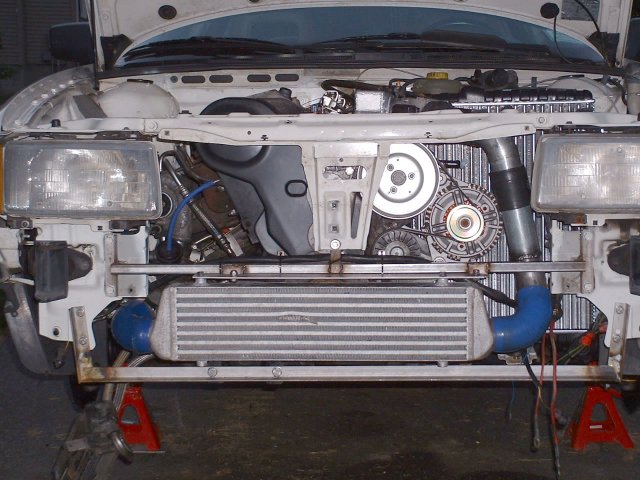

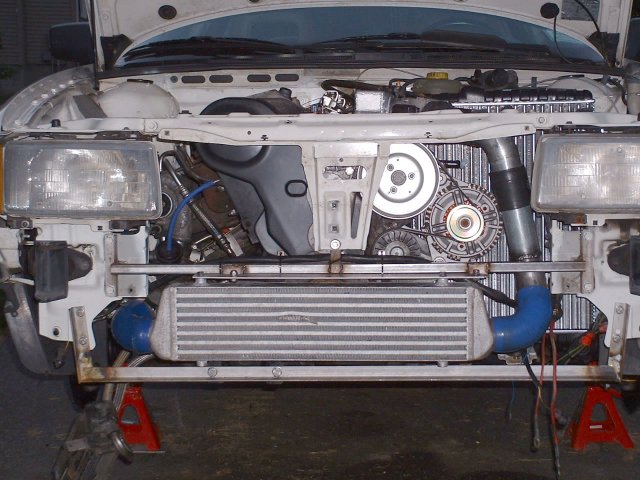

We also have progress on the radiator front! Which is to say, there is now a radiator in the front of the car.

Because the outlet for the aux. radiator interfered with the throttle cable (yeah I know I should have used one of Hank's intake manifolds), the 80 radiator was a no-go so I got a spiffy new 4KQ unit! Okay actually not all that spiffy, it's a cheesy Nissens one. It isn't even the right height - when sitting on the lower mount, one of the tabs the fan mounts to hit the frame, and the side mount was too low to meet up with the bracket. Has anyone else had this problem?

Anyhow, my solution was this:

...an M8 bolt with an M8 nut brazed to the top to act as an "extender" for the stud on the radiator mount. It looks lame but I think it'll work.

I also have, for now, officially given up on air conditioning. :( As you can sort of see in the first photo above, there really isn't room for the A/C condenser. It has clearance issues with the throttle body (yeah I know I should have used one of Hank's intake manifolds

), and my hacking away at the AAN alternator/AC compressor bracket really didn't yield enough space. So rather than mess with weird mounting to make the condenser clear, along with all the other A/C-related issues, I'm just gonna put that on hold for now. And without it, the radiator fits beautifully in its correct position with the correct (almost, I'm using a 4KQ shroud) fan.

BTW if anyone in the area is looking to *add* an aux radiator to their car, I have a good-quality (Behr I think) plastic-tanked 80q radiator in good shape that I'd love to trade for a 4KQ radiator (a real one, not Nissens) in decent condition.

Re: Eric's '90 80QT-to-be: progress!

Posted: Mon Sep 03, 2012 4:09 pm

by elaw

DE80q wrote:Very nice, so how many prototypes did it take until you got one that worked?

Just one! In addition to the one shown.

The first time around, I forgot the little shoulder on the outside to clear the pulley. Also I thought the bolt was M10 so I had the center hole drilled for that size bolt. When I got it back and *then* pulled the pulley & hardware out of the parts bin, I realized it was an M8 bolt. And it was a little too long. So I did up a new drawing with all the issues fixed, gave it to my friendly local machinist, and I've got a good piece!

Re: Eric's '90 80QT-to-be: progress!

Posted: Mon Sep 03, 2012 4:26 pm

by elaw

We also now have a resolution to "the intercooler question". With you folks' help I came to the realization that my bent explody Saab intercooler might not be the best choice for this car. So I temporarily abandoned that idea and for now I'm going with the one I was using on the 4KQ. I say "temporarily" because for semi-reasonable money (about $300) I can get a version of the Saab intercooler that's a little thicker and has welded end tanks which I think would be fantastic for this application. But for now to keep expenses down, I'm sticking with what I've got.

To get off-topic a little, I also made an interesting discovery. I was looking through some old Megasquirt logs, looking at intake temps to see just how crummy that cheap intercooler is. One thing I noticed is that after sitting for a while, the IAT *at idle* went higher than at full boost! And I think I know why that is... the IAT sensor on the AAN is located right next to the throttle. But at idle, the throttle is closed and the engine's intake air comes in a completely different place - at the back of the manifold via the idle valve. That means there's no air flowing across the sensor, and it heat soaks like crazy. Now that I know that, I'm going to mount the IAT sensor elsewhere. It doesn't make a huge difference on my setup with the MAF sensor, but anyone running standalone speed-density on one of these engines should take note, as it'll cause the mixture to be computed incorrectly at idle.

Anyhow, back to the intercooler story. Here's a photo:

You can see I fabbed up a crossmember to replace the stock 80 one which consumes a whole lot less space, allowing more room for the intercooler. My goal here is to make it fit with no mods to the bumper - I haven't actually tried putting the bumper on yet but I think it'll fit.

If you look closely, you'll see that the intercooler is mounted on a piece of bar stock which then attaches to brackets on the crossmember. I'm going to offer two explanations for that, and leave it up to you to choose which is the correct one:

1. A team of internationally-known aerodynamicists, using CFD software running on a supercomputer, and scale models in wind tunnels, determined that having a horizontal plate above the intercooler would encourage laminar airflow through the area, reducing drag and making the car go 20 MPH faster.

2. I messed up the location of the intercooler and was too lazy to fabricate new brackets and attach them to the crossmember. Instead I just drilled some holes in a metal bar to move the IC mounting location a bit to the left.

Re: Eric's '90 80QT-to-be: progress!

Posted: Tue Sep 04, 2012 6:38 am

by savagerocco

I'm gonna go with "B"....... lol Sounds like something I would have done, but I would have used "A" to explain it away also....

Re: Eric's '90 80QT-to-be: progress!

Posted: Tue Sep 04, 2012 6:41 am

by savagerocco

Also, very interesting take on the IAT. I am not sure if I have as bad a problem using the 3b manifold, but I am not sure in my mind whether airflow hits the IAT or not.

Re: Eric's '90 80QT-to-be: progress!

Posted: Tue Sep 04, 2012 6:54 am

by elaw

savagerocco wrote:Also, very interesting take on the IAT. I am not sure if I have as bad a problem using the 3b manifold, but I am not sure in my mind whether airflow hits the IAT or not.

Yeah I almost PMed you about it but figured you'd see it here. Looking at the MS logs, whenever the car is idling the IAT just goes up, up, up...

It's not visible in the photo, but I welded a bung for the IAT sensor in the steel tube that goes up beside the alternator, connecting the intercooler to the TB.

Re: Eric's '90 80QT-to-be: progress!

Posted: Tue Sep 04, 2012 6:57 am

by elaw

On a completely different subject, here's an interesting (and yes rather stupid) question. In different places in the Bentley it says the following:

1. The car's weight should never be put on the wheels unless the CV joints are installed.

2. When installing the CV joints, they should be tightened with the car's weight on the wheels.

So, uh, how exactly is one supposed to tighten the CV joints? :tard:

Re: Eric's '90 80QT-to-be: progress!

Posted: Tue Sep 04, 2012 7:02 am

by DE80q

You are supposed to install them, put the car down, then torque down the bolt. If you torque it down without the weight on it, it might not seat properly.

Re: Eric's '90 80QT-to-be: progress!

Posted: Tue Sep 04, 2012 8:20 am

by elaw

Here's another interesting random question. I just got my front rotors back from the machine shop (getting drilled to 5x112) and test-fit them on the car. These are CQ rotors and they're a little too tall - the caliper's going to need shimming and they don't even clear the dust shields!

The overall height of these rotors is 56.2 millimeters. I've already found out experimentally that 5KQ rotors at a height of 46.2mm are too short.

But wait... there are also 90Q 20V rotors which seem dimensionally the same as CQ rotors except their height is right in the middle of the two I mention above, at 51.2 millimeters.

So... has anyone doing a 5-lug conversion with UrS hubs tried the 90Q 20V rotors? It seems like they might fit perfectly...

Edit: if someone has a used rotor from a 90Q 20V with G60 brakes (ie the 276x25 mm rotor) that I could use for fit testing, I'd gladly pay a reasonable price for it!

Re: Eric's '90 80QT-to-be: progress!

Posted: Tue Sep 04, 2012 8:27 am

by DE80q

I am running 20v sedan rotors on mine with 80q spindles. I had to remove the dust shields and space out the caliper. With your setup being different, im not sure.

Re: Eric's '90 80QT-to-be: progress!

Posted: Tue Sep 04, 2012 12:33 pm

by my2000apb DrBeastCar

i may have that rotor let me got measure

Re: Eric's '90 80QT-to-be: them's the brakes...

Posted: Wed Sep 05, 2012 1:12 pm

by elaw

Well here you go... a photo of the CQ G60 caliper carriers and the CQ rotors:

The camera's not perfectly lined up, but they fit perfectly with about 4.6mm of washers between the caliper carrier and the steering knuckles.

As I mention above, according to the data I've gathered the 276mm rotors found on some 20V 90 quattros are dimensionally the same as these except they're 5 millimeters shorter. So the 90 rotors should fit well *without* having to put any washers under the calipers! Yes I know there's a 0.4mm discrepancy, but the clearance from the rotor to the caliper carrier is > 1.6mm on both sides so there's a little room for error.

The real question is, do I want to spend another $200 getting another set of rotors and getting them redrilled to 5x112 just to eliminate using the washers and maybe be able to fit the dust shield on? :?

Re: Eric's '90 80QT-to-be: them's the brakes...

Posted: Wed Sep 05, 2012 1:24 pm

by JonathanL

I'm gonna go out there and say no to that but keep in mind that there's no shields when you're sliding sideways thru dirt, snow and slush

Re: Eric's '90 80QT-to-be: them's the brakes...

Posted: Wed Sep 05, 2012 1:32 pm

by bimmerboy

I believe 5ktq with G60s have dimensionally the same rotors as the G60 90 20v cars, except they are 5x112. And I think that's what you're looking for.

Re: Eric's '90 80QT-to-be: them's the brakes...

Posted: Wed Sep 05, 2012 1:34 pm

by elaw

JonathanL wrote:I'm gonna go out there and say no to that but keep in mind that there's no shields when you're sliding sideways thru dirt, snow and slush

Yeah one thing I'm actually a little fuzzy on is what exactly is the function of the dust shields?

I can't help but notice that almost all street motorcycles (with disc brakes) don't have dust shields... but many dirt bikes do. That says to me that dirt/mud is the main issue, and those are conditions I don't encounter often.

Brake cooling-wise, I could see it going either way - the shields keeping air from the rotors, or directing more air toward them...?

Re: Eric's '90 80QT-to-be: them's the brakes...

Posted: Wed Sep 05, 2012 1:38 pm

by elaw

bimmerboy wrote:I believe 5ktq with G60s have dimensionally the same rotors as the G60 90 20v cars, except they are 5x112. And I think that's what you're looking for.

Actually, unless it varies by year or something, that is definitely not the case! I learned that the hard way, by ordering a set of those rotors and they didn't fit.

According to my research, the CQ rotors are 56.2mm tall overall, the 90Q ones are 51.2, and the 276mm 5000 rotors (which I think are the ones used with G60 calipers) are 46.2mm tall. As luck would have it, 46.2 is also the height of the stock 80Q rotors, but the fact I'm using UrS hubs and/or the fact I'm using CQ spindles changes the picture.

Re: Eric's '90 80QT-to-be: them's the brakes...

Posted: Wed Sep 05, 2012 4:28 pm

by scubadave

Is there a difference between the 90 20v spindles and the CQ spindles? I have been planning on swapping mine out for some b4 90 spindles as the spindle to upright bolts are much more burley. But if the offset for the caliper is different, ill stop that idea, but it may give you another option. I had assumed there was no difference in the offset of the spindles but the hubs were where they made the difference.

), and my hacking away at the AAN alternator/AC compressor bracket really didn't yield enough space. So rather than mess with weird mounting to make the condenser clear, along with all the other A/C-related issues, I'm just gonna put that on hold for now. And without it, the radiator fits beautifully in its correct position with the correct (almost, I'm using a 4KQ shroud) fan.

), and my hacking away at the AAN alternator/AC compressor bracket really didn't yield enough space. So rather than mess with weird mounting to make the condenser clear, along with all the other A/C-related issues, I'm just gonna put that on hold for now. And without it, the radiator fits beautifully in its correct position with the correct (almost, I'm using a 4KQ shroud) fan.