Building a 4.2 for my C4 project...

Posted: Sun Jun 19, 2011 11:22 am

I've been planning on an engine swap in my '97 C4 A6Q Avant for a while now and hopefully this will be a useful build thread for the V8 guys out there. In a perfect world I'd just import an S6 Plus from Europe since it has what I want: my '97 Avant with a V8 and a 6-speed. Since that's very difficult to do (though not impossible, one does exist Stateside) I decided I wanted to build my own version of this amazing engine and car...

If one wants to drop an Audi V8 into their C4 there are 2 differing options. The first (and easier way IMO) is the early V8s (3.6 PT and 4.2 ABH) from the V8Q models available here from '90-'94. The other option is finding a readily available ABZ A8 engine, lots of them to be had for reasonable $. The problem with the V8Q engine is that it is an earlier design with distributor ignition and looks dated in my opinion with that gargantuan air box. An advantage though is that the ABH block has mounting provisions for the C4 chassis and fits snugly in the C4 engine compartment with chassis-specific hoses and other parts available used in Germany. There's even a C4-specific engine harness and ECU.

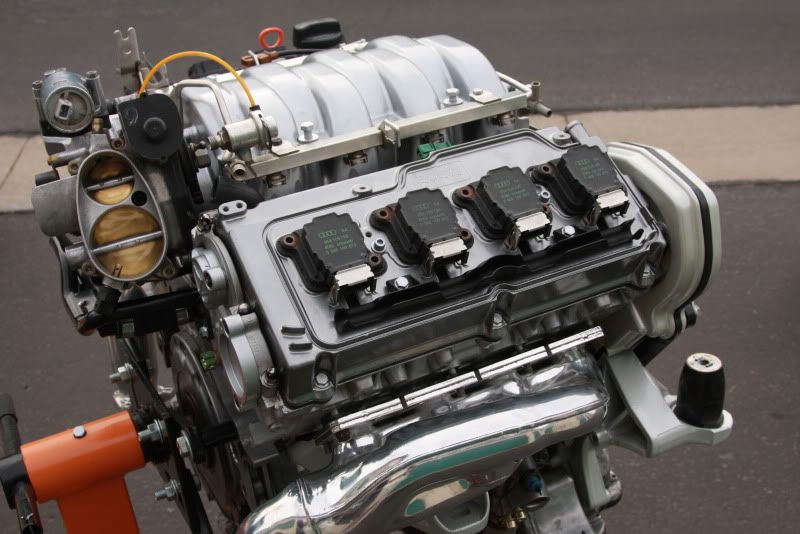

The ABZ is to me a far cleaner design, has coil-pack ignition and some other upgrades but was never designed to fit into the C4 chassis so the oiling system and mounts won't easily adapt to the C4. Some folks have adapted it to B3/B4/B5 chassis cars and it's definitely an affordable option but some engineering is in order to make it work. What is interesting/useful is that the ABZ heads will swap over to the ABH block straight away, exactly what Audi did with the S6 Plus though on the intake side they did tweak the cams and installed solid-lifters. So my engine will be just that: an early 4.2 block with the A8/S8 style coil-pack heads, manifolds, air intake and fuel delivery. Though I won't have the hot cams or higher compression 11.6:1 pistons of the Plus (instead staying with the ABH's 10.6:1 compression ratio) I still feel it will develop close to if not more than the ABZ's 300 h.p. With VEMS I might be able to see closer to 325 h.p. which rivals the S6 Plus.

In the past year I've been compiling parts for this swap, usually A8-specific things such as the air box, MAF, intake manifold, etc. Those parts can be shockingly cheap on Ebay these days: how does $25 for a throttle body or $40 for an intake manifold sound? With these first and second-generation V8s being nearly 20 years old they are quite reasonable to purchase, especially the more readily available ABZ. For my project I knew I needed to find both an ABH and ABZ engine to get the ball rolling....

In March the Audi gods came to the rescue when a used ABH long-block popped up on Audifans. It was in need of a valve job since the guides were shot but had a recent timing belt service and a bunch of new parts. Turns out the owner was a really legit guy who provided me dealer receipts for close to $3k in service before he finally just bought a lower mileage engine with hot cams and swapped out this one. I got it for around $500 shipped and it arrived in Phoenix a bit oily but very promising....

I've rented a cheap storage locker in Phoenix and this has become my de-facto shop while I get this project going. Since I'm in no major rush I decided to approach this project in two parts:

Part 1: Tear-down of the ABH and ABZ engines/ prep ABH bottom end for heads/ clean-up of parts for reassembly.

Part 2: Rebuild ABZ heads/final assembly of the new engine for install.

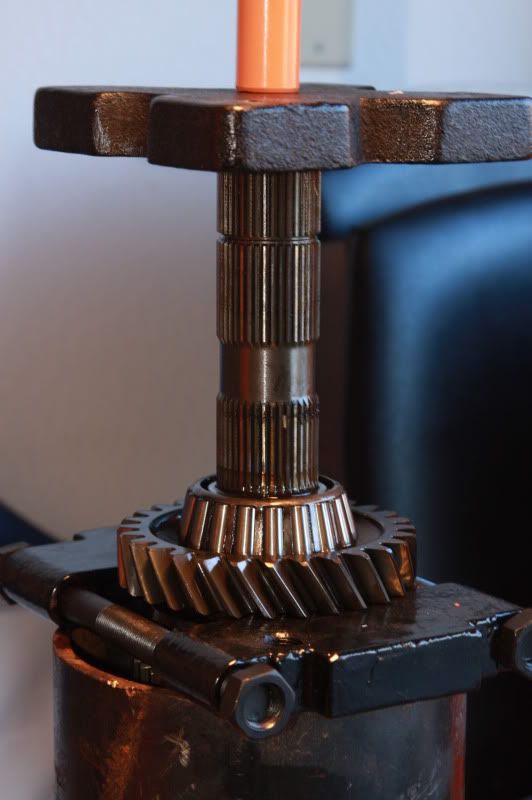

The ABH was in need of a good cleaning and while I had the time I also needed to swap out the upper oil pan to one from a manual transmission car (an S6 V8 in fact) since the bottom of the pan will interfere with the subframe on the C4. Here's a side-by-side comparison of the two pans:

Installing the new pan on the block:

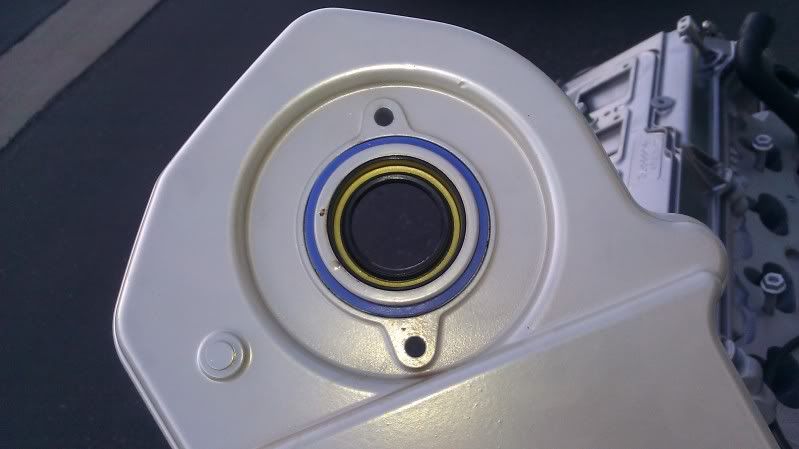

New HEPU water pump and fresh black paint for the harmonic balancer:

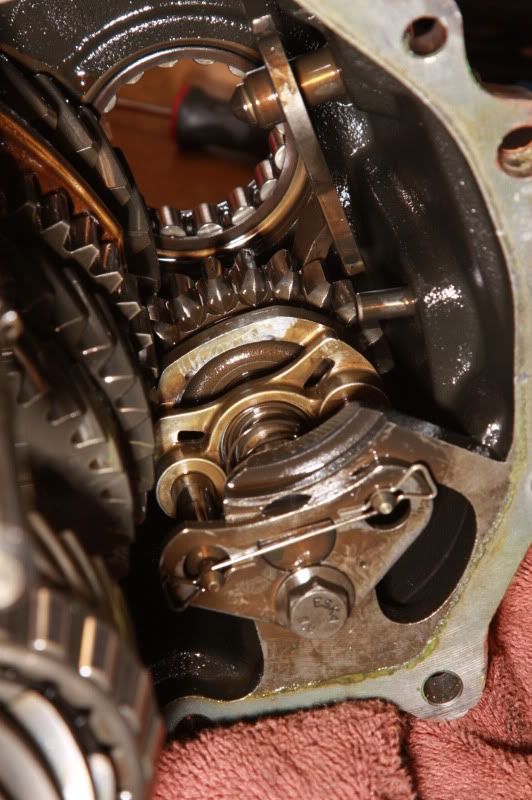

In May I located a good used ABZ engine so that will be the donor for the top-end parts. Just arrived in Phoenix from Florida and the tear-down commences...

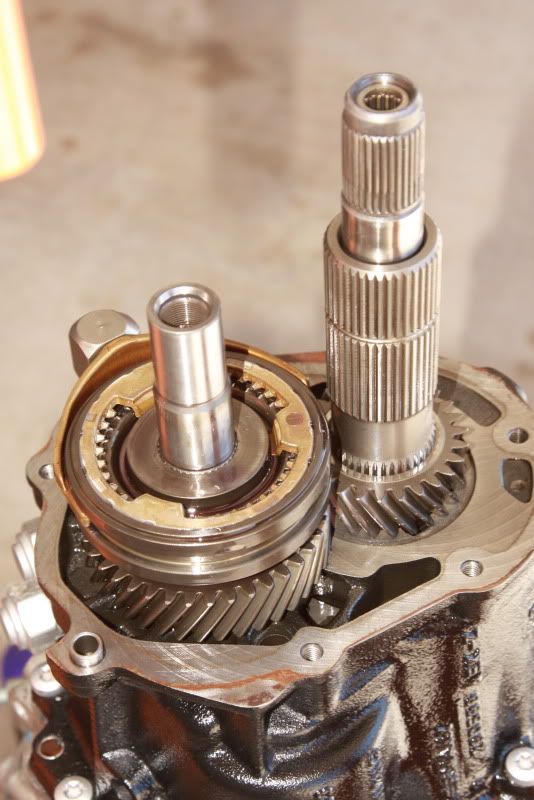

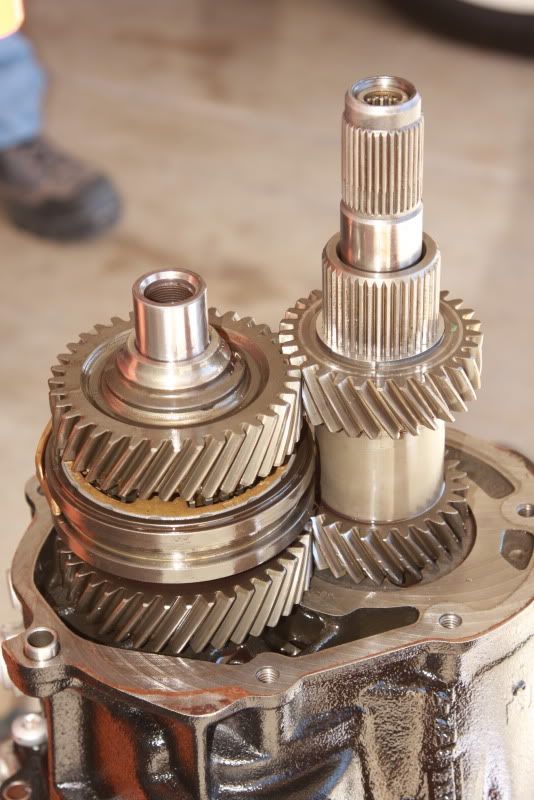

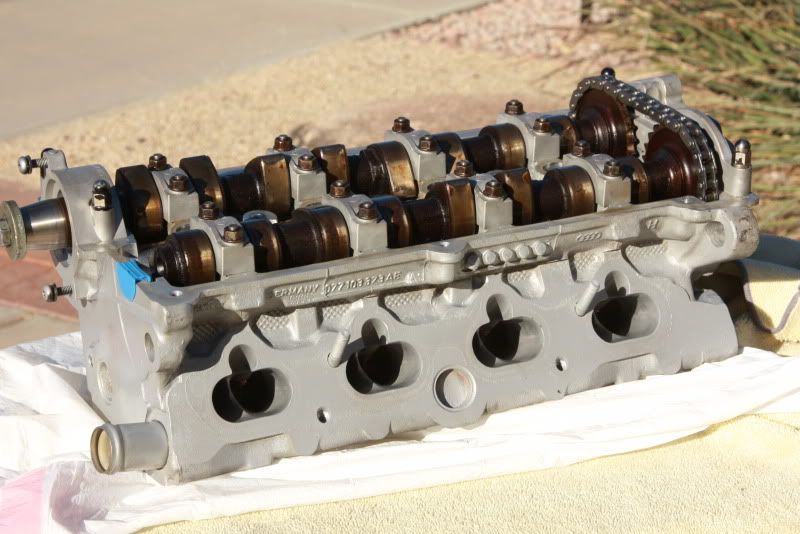

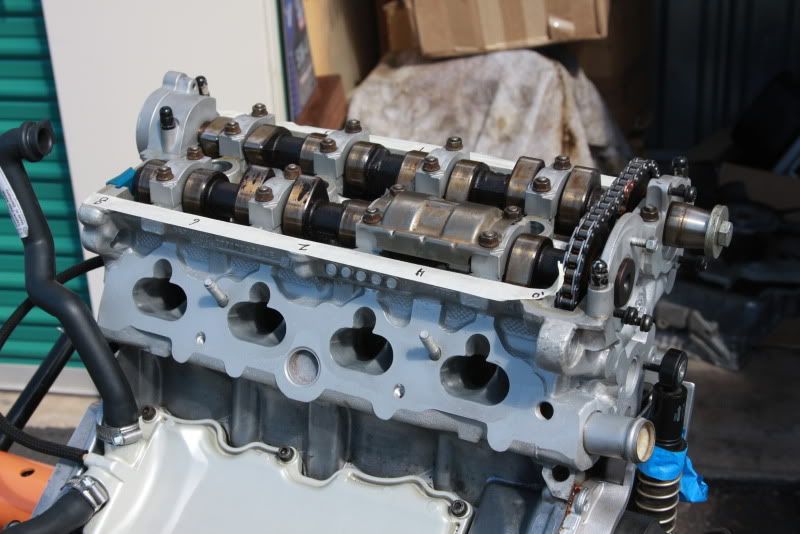

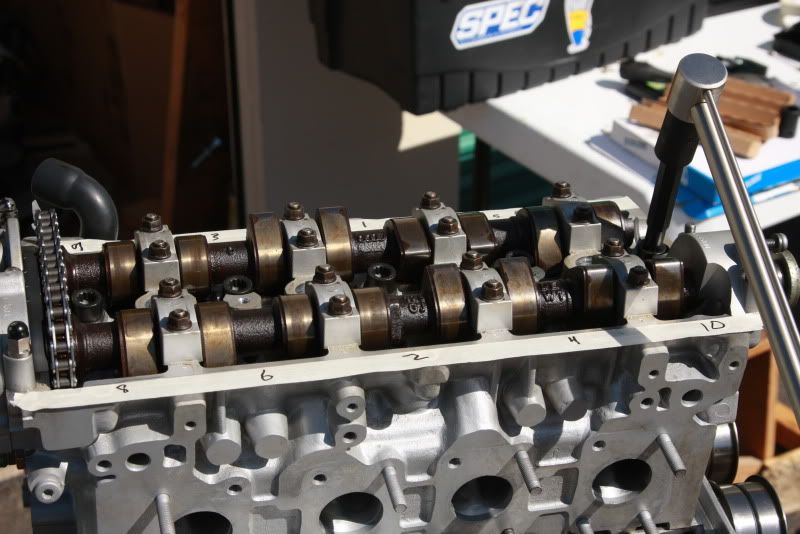

The coil-pack heads from the ABZ test-fit on the block:

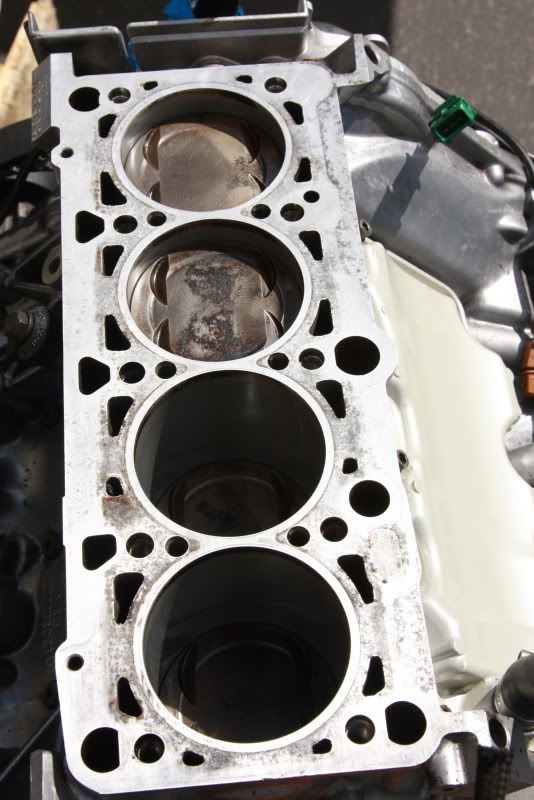

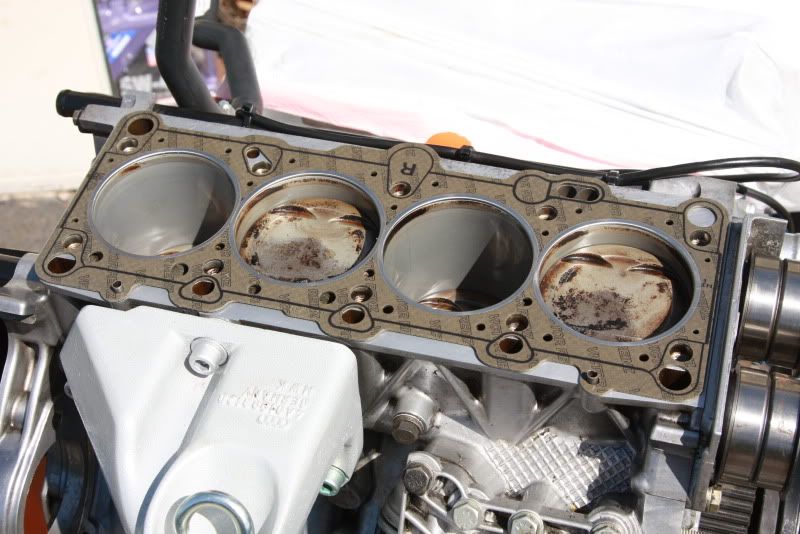

Plenty of room for the engine mounts it appears. Boy, this engine was dirty! Definitely the original timing belt and a bit of sludge in the engine, looks like I'll be scrapping the block but will investigate further. Nice to have all the misc. nuts and bolts, fuel rail, exhaust manifolds in one engine instead of having to source them individually. Lots of work to do, this will be a summer of bead-blasting and powder coating before the heads get rebuilt in the fall. Can't wait....

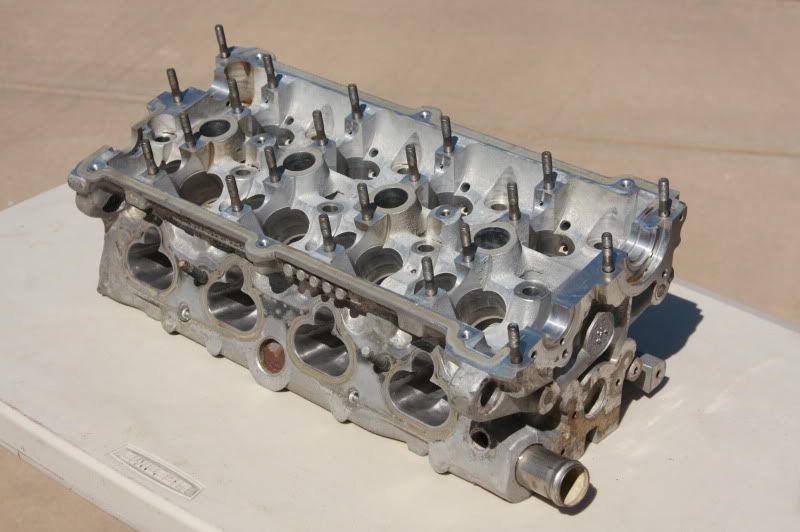

P.S.- Got the heads cleaned up and the intake ports sanded and reworked a bit:

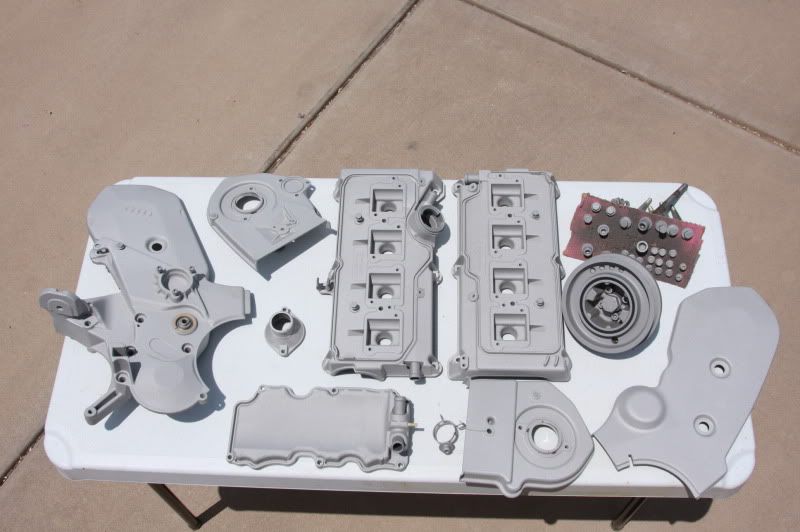

Ready for bead-blast and powder coat:

*****************************************************

A partial summary of the parts necessary to do this swap (so far):

ABH short block with the manual gearbox-specific "E" version upper oil pan

ABH starter and 110A alternator

UrS6 V8 oil cooler

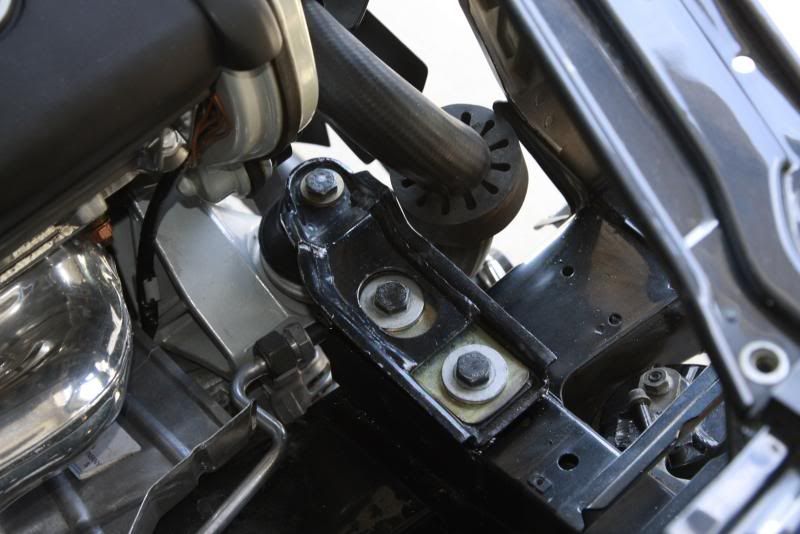

UrS6 V8 engine mounts and a/c bracket

UrS6 V8 A/C compressor/hoses

UrS6 V8 power steering hoses

UrS6 V8 rear coolant pipe and assorted coolant hoses

ABZ cylinder heads (rebuilt, ported and polished)

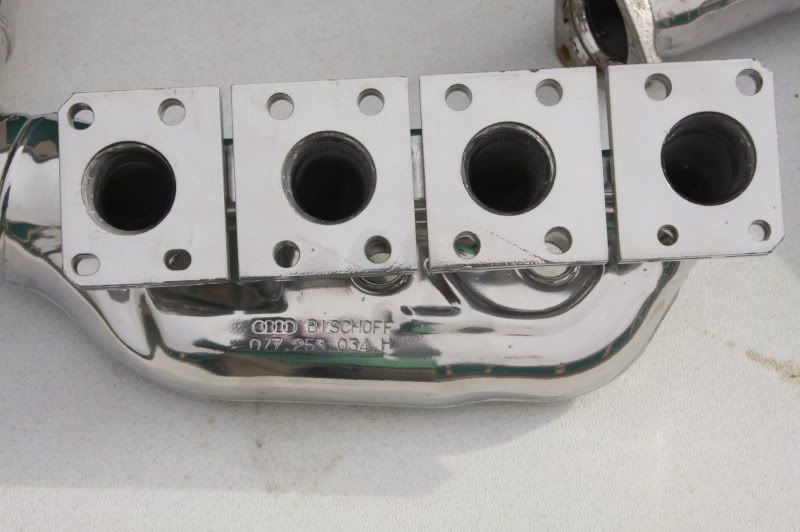

ABZ exhaust manifolds (ceramic coated)

ABZ intake manifold (partial port and polish), A8 throttle body, ISV, S6 Plus throttle cable

A8 Airbox, MAF and plenum hoses

S8 red V8 engine cover (I got the last one in the U.S. apparently)

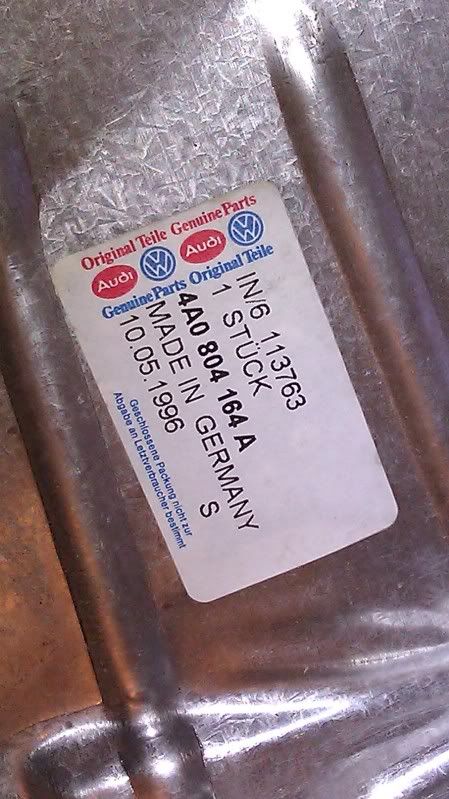

ABZ flex-plate with 60-2 ring and 034 flywheel insert for 228mm clutch

VEMS engine management with A8 engine harness (the exact harness has yet to be determined....)

*The engine mounts, intake manifold, timing belt covers and valve covers will all be bead-blasted and powder coated. Exhaust manifolds will be ceramic coated*

----------------------

EDU 01E 6-speed transmission

Southbend Stage 2 UrS6 clutch

-----------------------

Custom twin-pipe 2.25" 304 stainless exhaust with Magnaflow and Jetex resonators, similar in design to the BN-Pipes UrS system.

[/URL]

[/URL]