Basics:

- 1988 Audi 90Q Originally 20v

- Friend swapped stock 1.8T in and I bought it this way

- I swapped in built motor, BT and some Eurodyne software

- Suspension refresh + other little upgrades

- Some little wiring issues driving me crazy/tune won't let me stretch the legs of this turbo so time for a change

So, the change list:

- MS3

- New body harness

- Gut a lot of interior

- Custom brake and clutch pedal assembly

- Some metal work in the bay

- Clean up underside

- Bunch of new components, engine related. Fuel system, intake, intercooler, oil cooler etc.

And here is an overall plan of attack:

1. Strip the entire car of everything. (motor, trans, brakes, suspension, subframes literally everything) DONE

2. Strip interior of all wiring and trim etc DONE

3. Sand/grind/repair all metal work on the floors and paint/POR15 top/bottom of floors. (Leave/install mounting points for fuel system/lines, brake lines and exhaust hangers. DONE (what a relief)

4. Work on engine bay and mount pedal assembly. Figure out mounting of all 'liquid containers', begin work on the custom core support and structural bracing. Smooth and paint. DONE

5. Disassembly subframes, clean, seam weld, paint and re-assemble/install. DONE

6. Run engine harness and interior body harness. (Using this, or something similar http://www.leashelectronics.com/Pro-Str ... PS2012.htm and then also for my display I am going to use Bluetooth and a tablet in conjunction with stock gauges.)

7. Run new brake lines

8. Re-install motor, and re-do all plumbing of coolant/oil/air (motor is back in!)

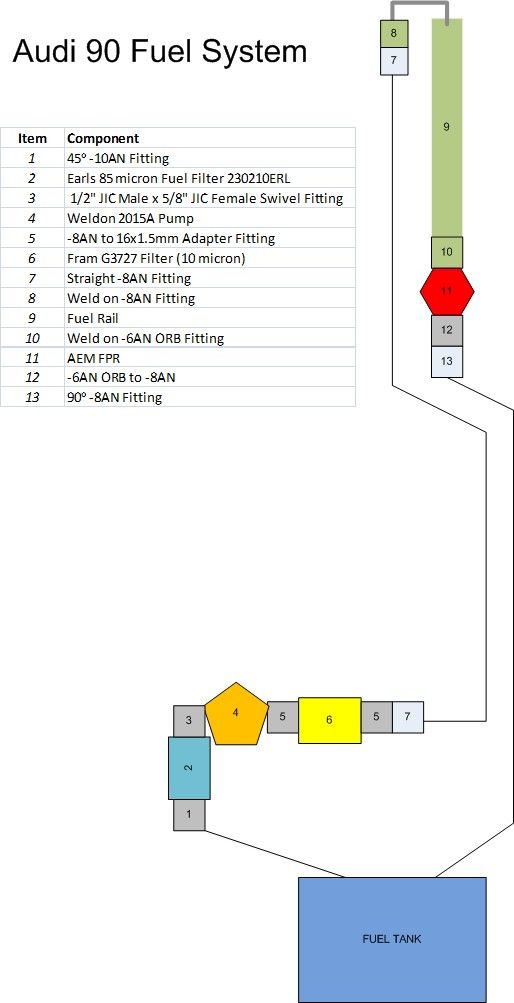

9. Install fuel pump/filter and run new lines.

10. Finish tubular radiator support for mounting of oil cooler, radiator and intercooler. DONE, wating on paint.

11. Re-install bumpers, carpet seats, some interior trim (keep hvac and stock body harness out)

I need the most help with how crazy to get with the bay. I love the functionality, strength and look of hacking a large seciton off in front of strut towers and doing round tube. BUT if I do that, my mounts won't work and for my purposes it won't be super benificial.

What I'm planning on doing is welding on some mounting plates where the bumper supports currently attach then from there make all the other stuff. Like a split mounting system. One section on top to hange litterally everying off of, and a bottom portion for added strength and securtiy. AKA the whole assembly with come apart like this:

Bumper first using stock ish mounting.

Bottom support will come off leaving the rad, intercooler and oil cooler suspended only by the top bar. I couldn't drive like this but it won't be falling off the car with the bottom removed.

In order to remove top support most all lines, air water and oil will be disconnect or the cooler will have to be unbolted from main support.

Anyone have a solidworks model of a 90 chassis engine bay? I was thinking about just drawing up what I'm thinking, but if there was a starting model around it would help a lot.

Enough words, here are some pictures.

Interior

So much crap:

Tonight I am going to start stripping everything, should be fun.