the german wrote:What is the plan for getting nuts or fasteners in there? access appears to be... challenging.

Maybe the idea is to have fun with and learn casting, but from a manufacturing standpoint this looks like it would be easier to get two flat plates machined and weld oval tube in the middle than go through all the work of casting then machining and cleaning up the casting. Especially if you're only making one.

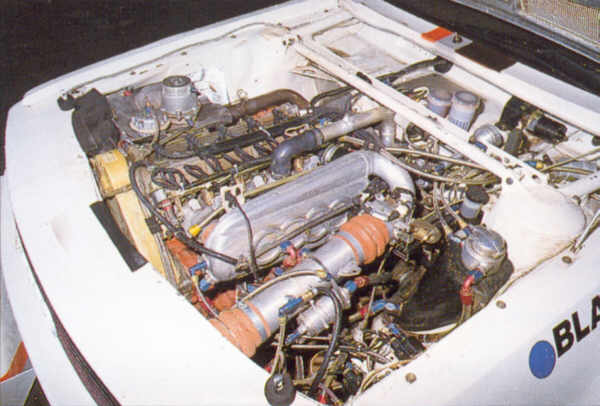

Plan is to use studs on the top. The bottom has been clearanced for bolts, or studs with the use of a socket to tighten the nut. The flange the ITBs mount to will also use studs. The manifold can't be clearanced properly for the upper fasteners without having holes or cuts where the ITBs need to mount or making the maifold wayyyyyyyyyyyyy too long. This manifold needs to be no longer than like 1.5" - 2" total due to the fact that the ITBs are already approximately 4.2" in length without the plenum which will add a good bit more length. This manifold complete will probably sit on the engine very similar to an actual S1 Quattro.

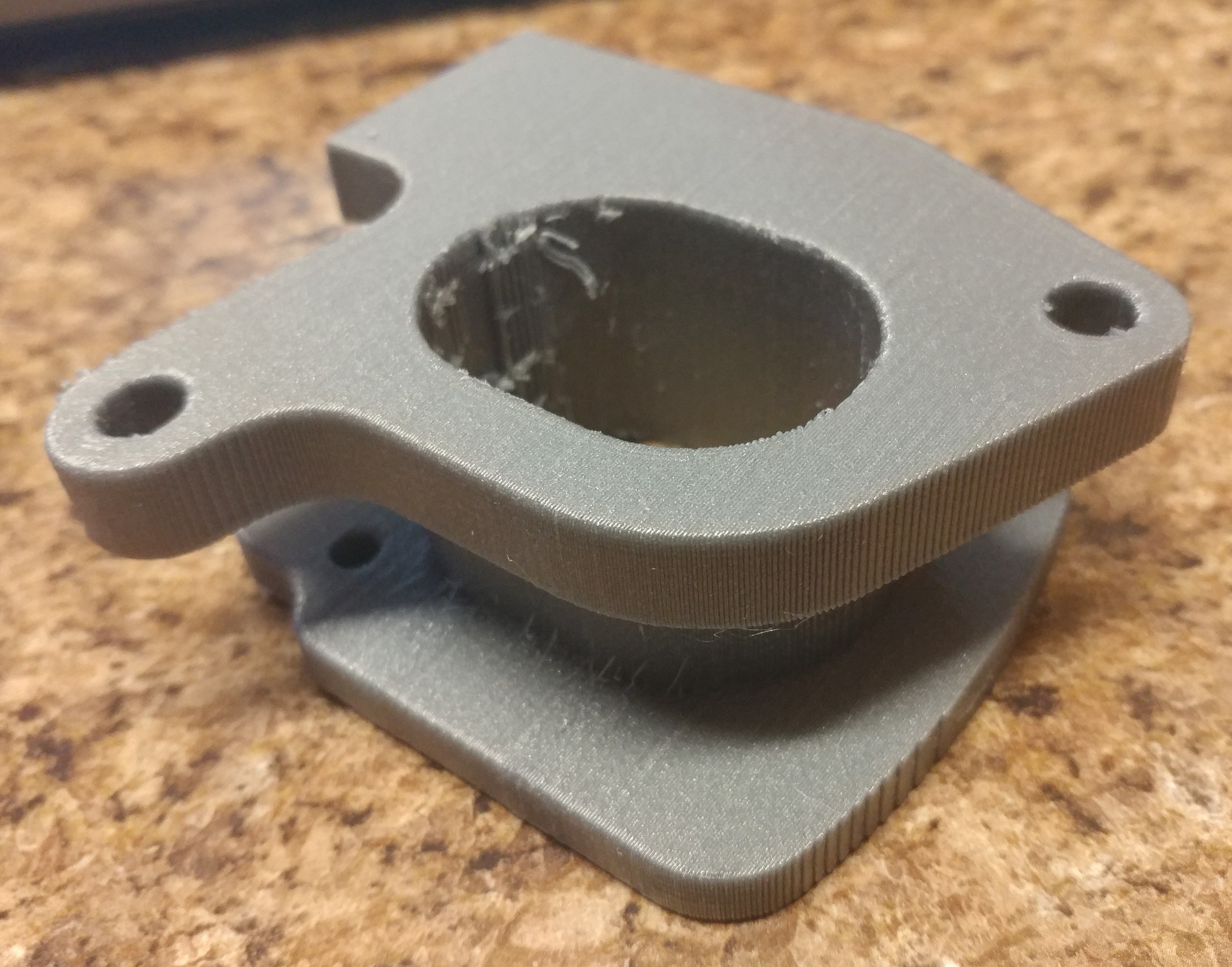

But I may tell him to hold off. The whole reason I asked Chris to 3D print me this was to be able to mock it up before casting it, or even machining parts because while I know this could work and works on paper/computer screen doesn't mean it will actually work how I think in the real world. Having always worked on 16vs with Webers or ITBs, I know the manifolds can be very tight. so I knew I could get away with a tight, very compact adapter manifold. But obviously at some point too compact is just too compact and it doesn't work.

Here is the portion that Chris has printed so far, he posted it on page two. Those images I posted are deceiving and don't show how much space is really there, although it's still tight. Around 3/4" between flanges if I remember right. I'd considered increasing that dimension to around 1" to 1.25" for added room because that would still leave the overall length within the specs I need it to be. But this is really why I need a prototype before jumping head first into making a final product.

mrdeye wrote:Yes!! That is very complex for your 1st time at casting parts. Depending on how you make the tool you would have 5 cores to deal with. The cores would make the 5 holes in the part. It's your call, but you might be better off finding a chunk of the alloy specs that you want and have it machined. Make'n parts is cool though!

Yeah, it's a bit of a doozie for a first timer, but I'm not too worried about it. I'm patient and eager to learn this haha

But I do agree with both of you that machining a chunk of aluminum would be easier by a long shot. Whether the whole piece was machined out of one piece or multiple pieces were machined and welded together. We'll see how things go. I really want to cast it so I can say I did it and so I could learn the process, but otherwise machined is good enough for me. As long as I can bolt my ITBs to it, it doesn't matter too much.

I'll probably end up holding off a little while longer on attempting to cast this until I can get a completed prototype either from Chris if he can find the time or I'll make on out of plastic pieces cut on my friends table top CNC milling machine. I think maybe the excitement of getting this all done is causing me to get ahead of myself